石油套管是用于支撑油、气井井壁的钢管,以保证钻井过程进行和完井后整个油井的正常运行。每一口井根据不同的钻井深度和地质情况,要使用几层套管.套管下井后要采用水泥固井,它与油管、钻杆不同,不可以重复使用,属于一次性消耗材料.所以,套管的消耗量占全部油井管的70%以上。

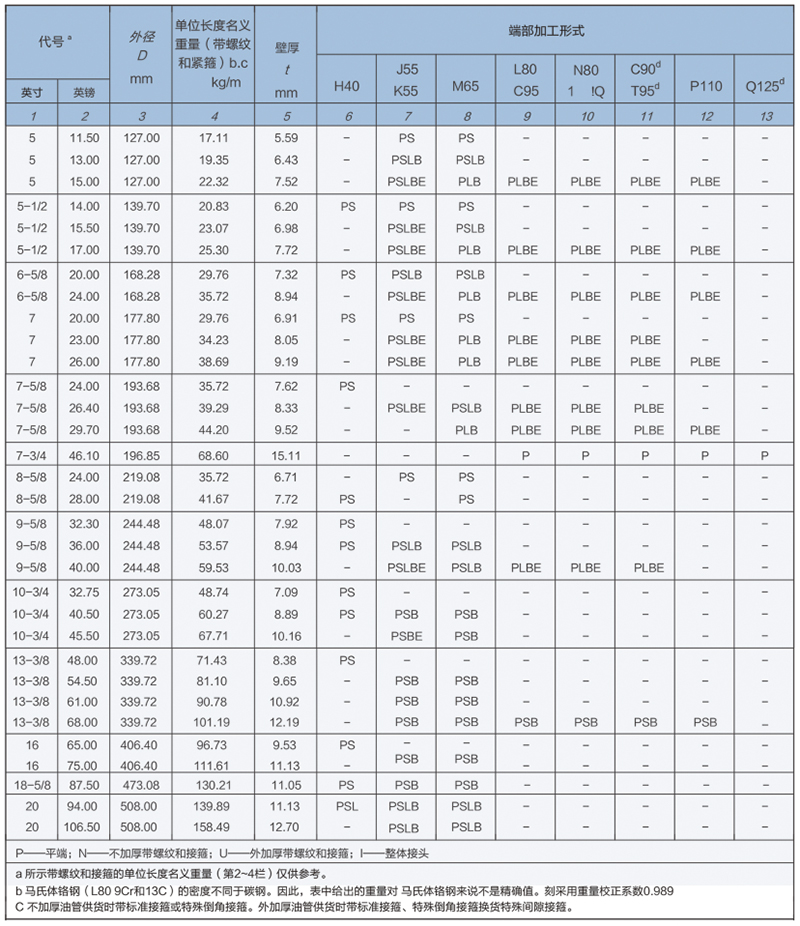

按美国石油学会标准APISPEC5CT,套管可生产加工钢级为J55,K55,N80,P110 等。规格从60--508 K55可加工扣型有STC(短圆扣),LC(长圆扣), BC(偏梯扣),VAM(偏梯扣)等扣型。

Petroleum casing is used to support the wellbore of oil and gaswells in order to ensure the normal operation of the whole well after drilling and ompletion. Each well should use several layers of casing according to different drilling depth and geological conditions. Cement cementing is used after casing goes down. It is different from tubing and drill pipe. It can not be reused. It belongs to disposable consumable material. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes.

According to APIspec5ct standard of American Petroleum Society,casing can produce processed steel grade J55, K55, N80, p110, etc.Specifications from 60 to 508 K55 can be processed button type STC (short round buckle), LC (long round buckle), BC (partial ladder buckle), VAM (partial ladder buckle) and ther button type.